Do you recognize the feeling that your supplier is playing games with you? That he’s not delivering what’s agreed upon? And perhaps you suspect that not delivering quality is a strategic choice? In the meanwhile you spend at least twice as much in performing acceptance tests? And lose even more time on discussing issues that are obviously defects?

Or are you more familiar with the case that your customer actually does not know what he wants? That every ‘stakeholder’ has a different opinion? Or worse, your stakeholder, has a different opinion every time you meet? And thinks you have all the time in the world to act upon these wishes? Simply forgetting that your profit margins are minimal, as this was the only way to get the order.

If you recognize either situation and could use some help, Quality Level Management, QLM for short, is the answer for you.

In this first blog I will answer four basic questions on Quality Level Management (QLM):

- Why QLM?

- What is QLM?

- How does QLM work?

- Why is QLM so useful?

In the following posts I’ll dive into concrete issues both customers and supplier have to deal with. If customers and suppliers recognize problems early, it becomes easy to implement appropriate measures early.

Why Quality Level Management?

To manage and control quality is difficult to achieve within one party. Problems seem to escalate in case more than one party is involved. Physical distance, cultural differences and difference in vision and strategy lead to misinterpretation of requirements, too little involvement of the business and poor quality processes. All are known causes for poor product quality. Quality level management helps to overcome these problems.

What is Quality Level Management?

Quality Level Management (QLM) is managing quality in the case of outsourcing of IT-related products and services.

Managing Quality:

There is always a balance (or struggle) between time, budget, scope and quality as depicted in the iron triangle.

The time, budget and scope are quantifiable and often much easier to define and measure than quality. Therefore time and money are primarily used to select suppliers and to control projects. How to manage and control quality when it is so hard to pinpoint what the desired quality is?

Outsourcing:

In Quality Level Management the term outsourcing is used to denote the fact that several parties are involved: at least a customer and a supplier. This can be a supplier abroad, but also another department in the same company. When using the term outsourcing in case of QLM this also refers to:

- Off-shoring;

- Near shoring;

- Joint venture;

- Fully owned;

- Turnkey;

- Indirect;

- Right sourcing;

- Multi sourcing;

- Best shoring;

- Back shoring.

In all cases the difficulty is that different parties are involved. Different parties may have different goals. The basic notion of us-versus-them causes parties to behave in their own interest instead of working together as partners striving for a win-win.

IT-related products and services:

Quality Level Management focuses on IT-related products and services. This can range from a bank application, to a tunnel, to a medical device to a printer. Although QLM focusses on IT many measures that can be taken as part of QLM are also applicable to other domains.

How does Quality Level Management work?

Quality Level Management first looks at the context of the outsourcing relationship.

- Type of products outsourced;

- Type of services outsourced (design, development, testing, maintenance or a combination);

- Type of organisations;

- Type of contracts;

- The (cultural) differences between customer and supplier;

- The desired level of quality.

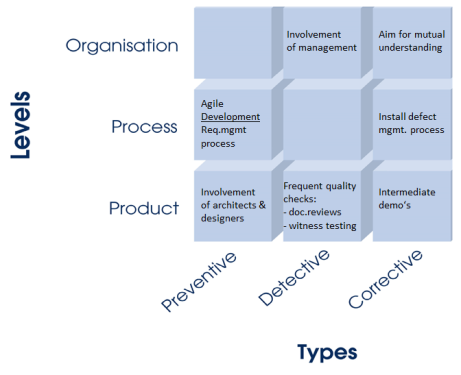

Then it identifies problems at three levels: product, process and organisation. Based on the context and the problems at hand appropriate measures are selected. For this the QLM-model is used. The QLM-model helps to determine a balanced outsourcing strategy that focuses on meeting goals and expectations in terms of time, budget and last but not least in terms of quality.

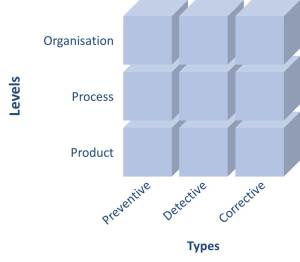

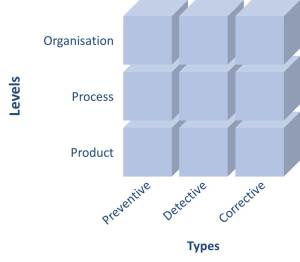

The model for Quality Level Management has two main dimensions:

- Levels at which measures can be taken: the organisation, processes and products;

- Types of measures: preventive, detective and corrective.

A balanced strategy uses a selection of quality measures out of the nine areas of attention in the QLM-model.

Why is Quality Level Management so useful?

Most existing models focus only on organisational and process aspects. The QLM-model focuses on measures to be taken at all levels; including the product level. As problems at product level often are caused by problems at organisational level, this complete focus helps both customers and suppliers to pinpoint the actual problem and select appropriate measures.

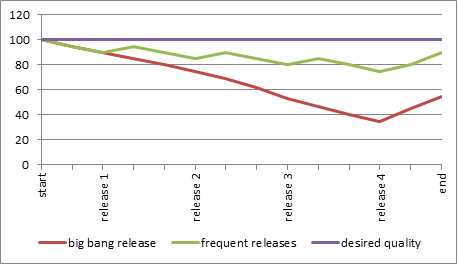

The QLM model can be applied at any point in time. At the start of an outsourcing relation most focus will be on preventive measures and defining detective measures. As the relation prolongs the focus shifts to corrective measures. Being able and willing to make necessary changes is crucial for obtaining a fruitful relationship and to obtain the desired level of quality.

Next posts I will discuss some problems customers and suppliers have in managing quality in outsourcing of IT-related products.

Jeanne Hofmans

h user stories of sufficient quality. Sometimes the development team accepts work not yet properly refined, thus they have to refine it themselves within the sprint. In other occasions a team refuses the work assignments as being not ready to take into development. One way or the other, it slows the velocity of delivering quality software. And the preparation work done by the business people deflates in value (if you are looking for experiences, please google ‘definition of ready’ it results in many experiences and opinions).

h user stories of sufficient quality. Sometimes the development team accepts work not yet properly refined, thus they have to refine it themselves within the sprint. In other occasions a team refuses the work assignments as being not ready to take into development. One way or the other, it slows the velocity of delivering quality software. And the preparation work done by the business people deflates in value (if you are looking for experiences, please google ‘definition of ready’ it results in many experiences and opinions).